Piston Pumps

Piston pumps are a type of reciprocating positive displacement pump that use one or more pistons to transfer fluids. They are known for their high-pressure capabilities and are commonly used in applications that require precise fluid delivery and high-pressure pumping. Piston pumps operate by using the reciprocating motion of pistons to create suction and discharge strokes. Here are some key features and components of piston pumps:

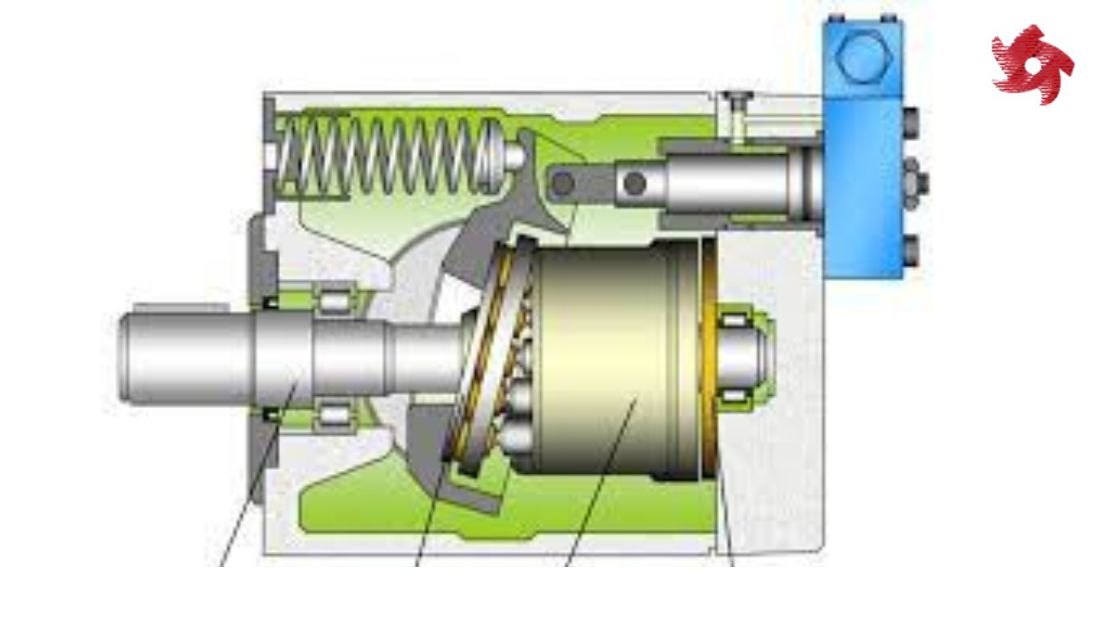

- Piston: The piston is a cylindrical component that moves back and forth within a cylinder. It is typically sealed against the cylinder walls with piston rings or seals to prevent fluid leakage. The reciprocating motion of the piston creates the suction and discharge strokes.

- Cylinder: The cylinder is a cylindrical housing in which the piston moves. It is designed to provide a sealed chamber for the piston and fluid, allowing the fluid to be drawn in and discharged as the piston reciprocates.

- Inlet and Outlet Valves: Piston pumps have one-way valves, often referred to as inlet and outlet valves or suction and discharge valves. These valves allow fluid to enter the cylinder during the suction stroke and prevent backflow during the discharge stroke. The valves ensure a unidirectional flow of fluid through the pump.

- Drive Mechanism: Piston pumps require a drive mechanism to convert rotary motion into the reciprocating motion of the piston. This can be achieved through various means, such as a crankshaft, eccentric cam, or hydraulic drive.

- Inlet and Outlet Ports: Piston pumps have separate inlet and outlet ports for fluid entry and exit. The fluid is drawn into the pump through the inlet port during the suction stroke and is discharged through the outlet port during the discharge stroke.

Piston pumps offer advantages such as high-pressure capabilities, precise fluid delivery, and the ability to handle a wide range of fluids and viscosities. They are commonly used in applications such as hydraulic systems, pressure washers, oil and gas industries, and high-pressure water pumping.

Proper maintenance and regular inspection of piston pumps are important to ensure their reliable and efficient operation. This includes monitoring piston seals, valves, and cylinder wear, as well as ensuring proper lubrication and alignment of pump components. It’s important to follow manufacturer guidelines and recommended maintenance practices for piston pumps to maximize their performance and longevity.

Related Links

Multiple keywords

pumpmanufacturer, pump, aoddpump, aodd, aoddpumps