This strategic alliance underscores the company’s commitment to simplifying our customers’ digitalization needs and investing in the future of automation.

What is the role of Single Pair Ethernet (SPE) in automation?

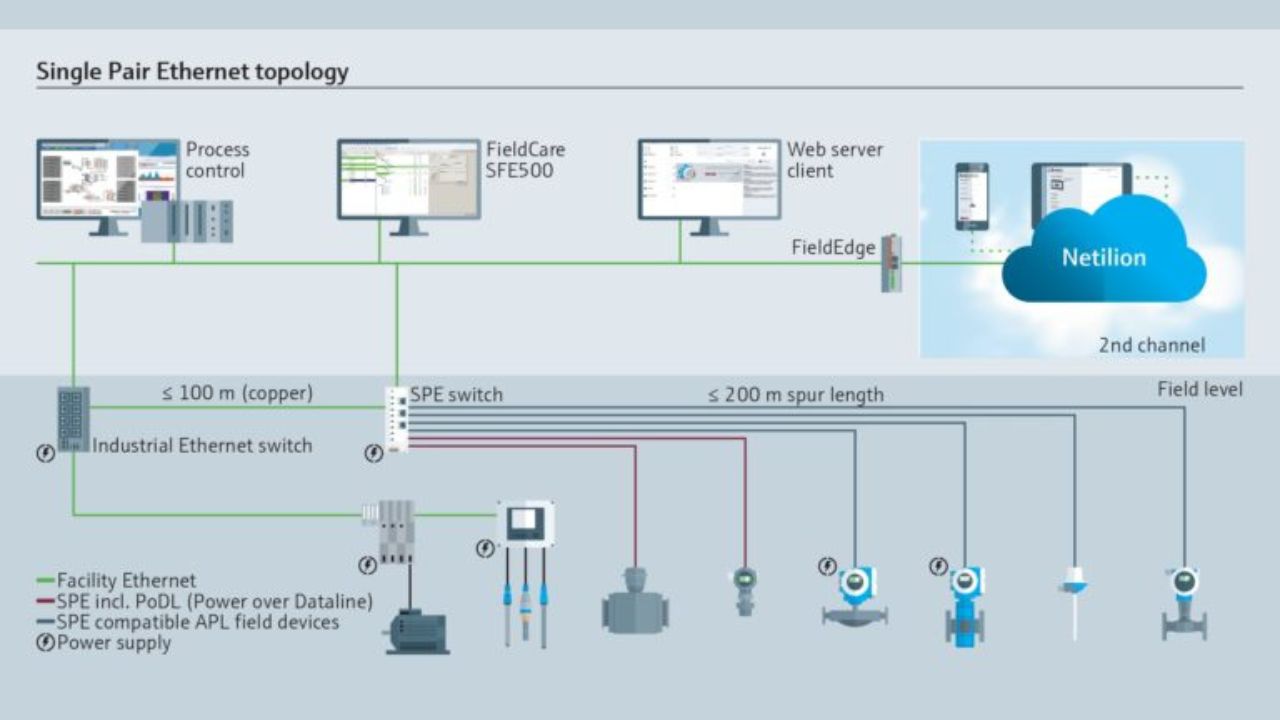

SPE is a game-changer, especially for the food & beverage and life sciences industries. In highly automated process environments without extensive hazardous protection, SPE delivers a variety of benefits: it realizes the advantages of an Ethernet connection – such as the high speed and volume of transmitted data – at field level with a simple two-wire cable, which transmits both data and energy. The commissioning process is simplified with easy wiring and connectivity.

Moreover, the automation pyramid is flattened as other systems can now connect via Ethernet at field level, fostering seamless integration and interoperability. Data from smart instruments in the field can be processed in upper layer applications. This results in optimized machine design, connectedness and improved overall equipment effectiveness (OEE). For this reason, SPE proves its worth as an open, cost-efficient and future-proof technology that is ready for the Industrial Internet of Things (IIoT).

Joining forces increases customer value

Endress+Hauser is dedicated to easing the digitalization journey for its customers. By joining the Single Pair Ethernet System Alliance, the company is demonstrating its trust in the members that are committed to shaping the future of automation together. Customers benefit from interoperability by driving business with the members of the SPE System Alliance. Close to 75 members are creating the largest ecosystem of SPE products, creating freedom of choice for customers. Endress+Hauser’s entrance into the partnership opens the door for sharing knowledge and expertise to deliver superior solutions.

Prospective product portfolio

To offer customers the chance to grow their digitalization capabilities and realize all the benefits of SPE, Endress+Hauser is now working on its portfolio of field devices with SPE. A clear goal is to create a harmonized approach, comparable to the manufacturer’s Ethernet-APL devices. The comparison with Ethernet-APL – another industrial Ethernet technology – shows that a uniform connectivity and certification concept is essential, whether for hazardous or non-hazardous areas. This gives customers across diverse industries more flexibility to profit from the benefits of a well-functioning data highway.

Source: Endress+Hauser AG