“Wastewater treatment plants that consume large amounts of power in the municipal area owing to their demanding process steps depend on technologies that are both energy efficient and powerful,” says Michael Brinkmann, Director of Global Sales at Vogelsang. He also says: “The HiCone gives wastewater treatment plant operators a durable, highly efficient pumping technology that can be flexibly readjusted to different pumping tasks and operating parameters.”

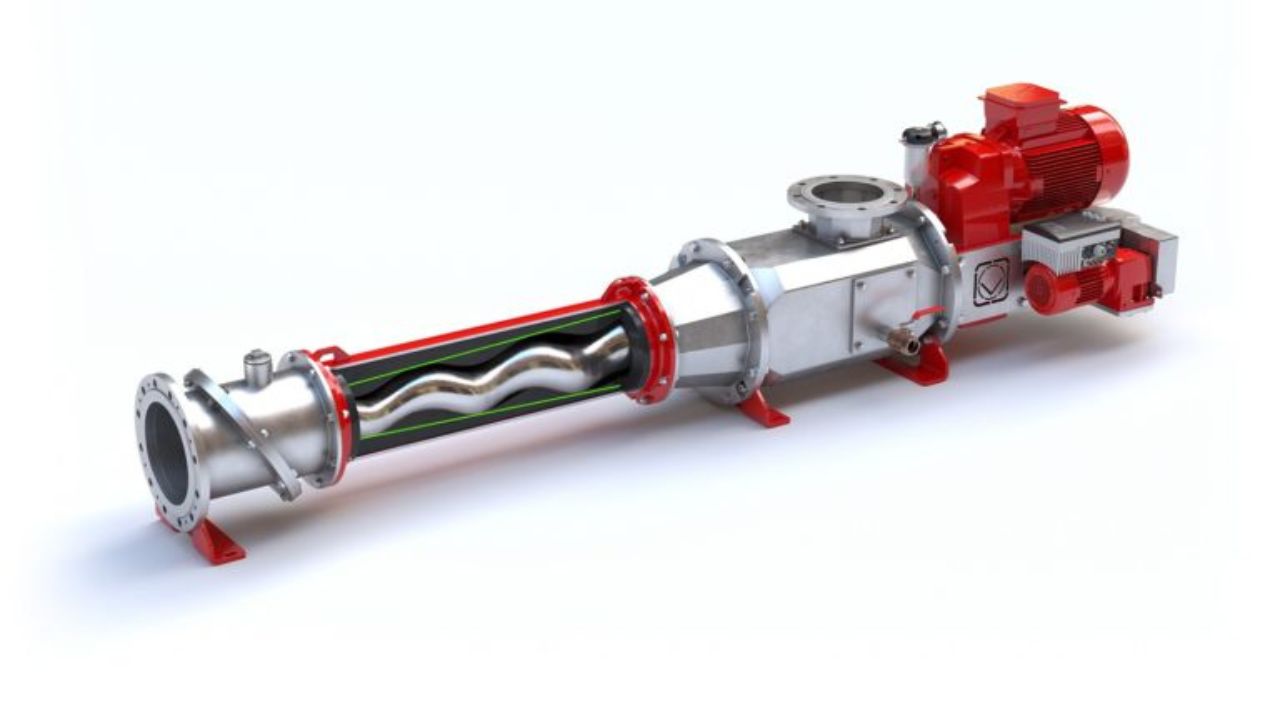

HiCone: Readjustment via remote maintenance

The HiCone features a conical rotor-stator geometry and a clever adjustment system. Precise readjustment of the rotor compensates for wear. This ensures constant pumping performance at a high level of effectiveness without costly and time-consuming parts replacement. At the same time, the product has a status display that informs users about the pump’s condition continuously and in real time. The HiCone thus requires maintenance less often, and it can be planned better. If the HiCone is equipped with the automatic adjustment option and connected to remote maintenance, the rotor can be readjusted as needed from the control room with no time-consuming travel and maintenance. Wastewater treatment plant operators with pumps in remote use benefit from this, in particular, at pump stations, which usually are not monitored by specialists on site.

Conical pump for high pressures up to 12 bar

The HiCone is also designed for higher pressures of up to 12 bar. For wastewater treatment plant operators, that means the HiCone can even handle process applications with high pressures that usually require a long, two-stage progressive cavity pump. Wastewater treatment plant operators reduce costs, the energy needed for their operations, and space requirements when they purchase the HiCone.

Shredding technologies for smooth wastewater treatment

Moreover, Vogelsang is presenting its large range of products featuring powerful shredding technology. The XRipper XRG and XRipper XRC twin-shaft grinders in particular are suitable for retrofitting in the sewage system, such as in open channels or shafts. The XRipper XRP is the compact inline variant for installation in pipelines. All models in the XRipper series are equipped with robust, durable one-piece Ripper rotors. They shred foreign material in wastewater, such as wet wipes, cleaning cloths, rags and pieces of wood, to unproblematic sizes. By doing so, they protect downstream components, including the pump technology, against blockages and damage.

Vogelsang is also showing the modified inline variant of the macerator RotaCut RCQ. This type of RotaCut is used in wastewater treatment plants during sludge treatment, among other things. It can be quickly installed in straight pipelines and thus retrofitted without laborious adjustments. With its contact-based cutting principle, the macerator reliably shreds fibres and solids like hair and cotton swabs in wastewater and sludge. The integrated heavy material trap separates stones, metal parts, and other foreign bodies, which can be removed from the service flap. The service flap hatch can be positioned flexibly.

Rotary lobe pumps: Tried and tested in the wastewater sector

Furthermore, Vogelsang will be providing information about the rotary lobe pumps of the VX and IQ series. Vogelsang’s powerful rotary lobe pumps have already proven themselves around the world in a very wide range of applications that involve pumping both sludge and wastewater.

Source: Vogelsang GmbH & Co. KG