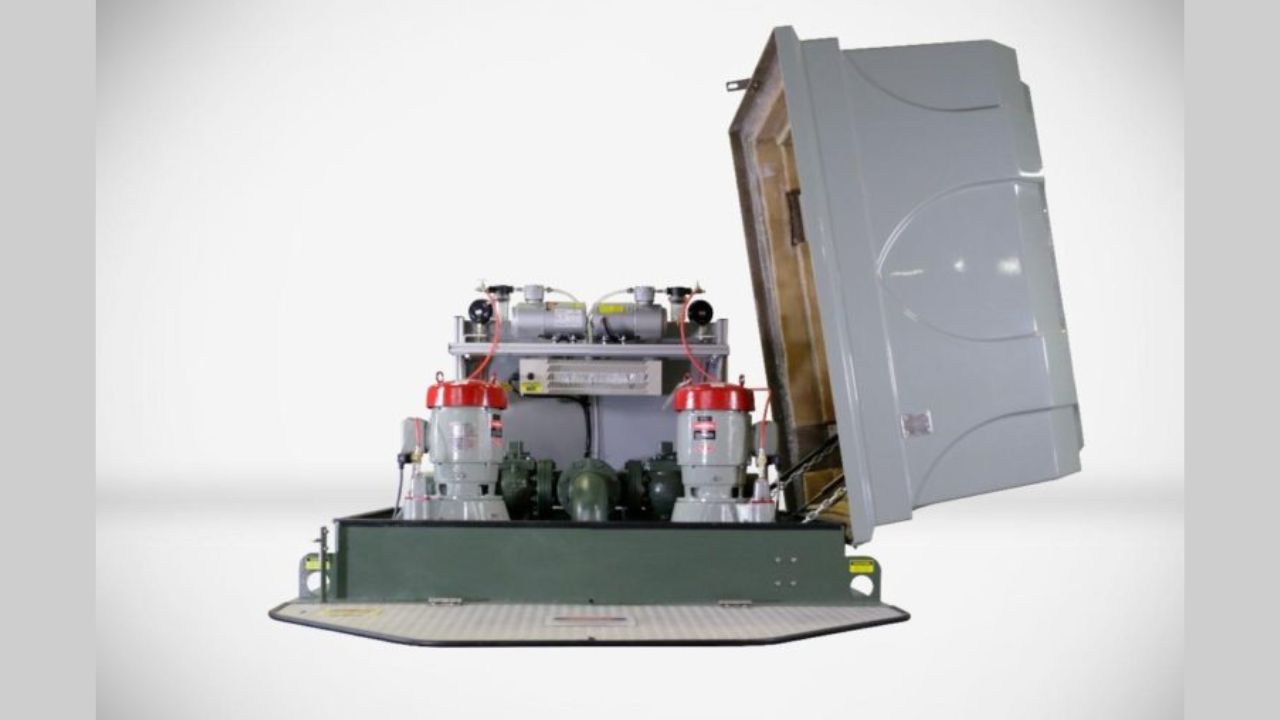

Unlike submersible pump stations, all mechanical equipment is safely located and easily accessible above ground and outside the wet well, eliminating confined space hazards during routine maintenance and operation. The EV Series 1000 features a tip-up hood, allowing for easy and immediate access to all mechanical and electrical components.

The cost savings for maintenance and operation are proven and well-documented. For example, a Kansas municipality conducted a study of the repair and maintenance costs of 32 S&L above-ground pump stations compared to 21 submersible pump stations in the same sewerage network over a period of 12 years. The results showed that the S&L pump stations had nearly 56% lower operating expenses, resulting in maintenance and parts savings of $2,750 per station per year.

The EV Series 1000 pump station is equipped with S&L STAR ONE Non-Clog Pumps, which are centrifugal solids-handling pumps that last three to five times longer than a typical submersible pump. These pumps also offer higher efficiencies across the range of pumping conditions. For extra trash-filled applications, the mono-port X-PELLER impeller is designed to pass through flushable and heavy ragging and stringy material.

The EV 1000 also features standard relay logic controls. Easy to operate and repair, relay logic – with float switch level controls – is a base control system made for operators. Optional RapidJack check valves eliminate the need for time-consuming valve disassembly and interim piping realignment and are easily accessed by removing just four bolts. Another popular option is the DURO-LAST 316/Lean Duplex Series 2100 Stainless Steel Baseplate which comes with a 25-year warranty, the highest level of protection available in the industry.

Source: Smith & Loveless Inc.