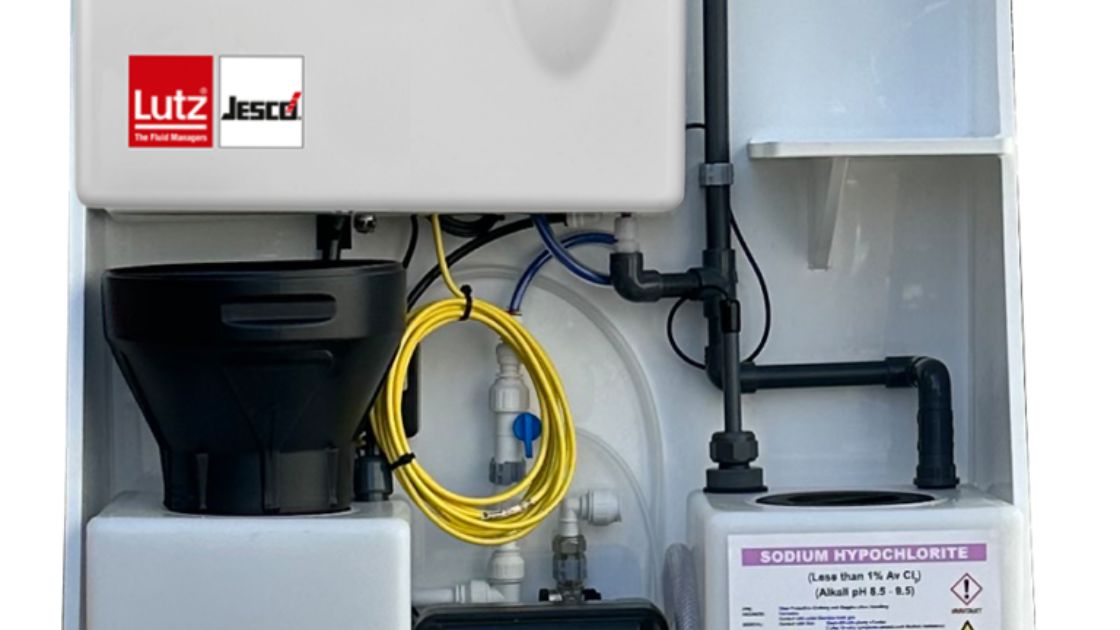

Some swimming pool operators avoid the use of commercially available chlorine products to disinfect the pool water, as these often act as a deterrent due to their complexity. Many are therefore looking for a safer and simpler alternative. “Chlorination systems require safety equipment and careful, professional handling with regular staff training. These requirements often make their operation complex and cost-intensive,” confirms Thomas Beutel, expert for swimming pool technology and dosing systems engineering at Lutz-Jesco GmbH. To offer an alternative, the company is presenting the MINICHLORGEN T 30 Skid I at Interbad 2024. The electrolysis system generates the disinfectant sodium hypochlorite directly on site from commercially available salt. This produces free chlorine in the water, which reliably inactivates most microorganisms, including bacteria, fungi and algae. The maintenance costs are manageable and the guarantee on the electrolysis cells means that the operating costs are also low. MINICHLORGEN T 30 Skid I is therefore a practical solution for swimming pool operators who are looking for effective water disinfection with little effort and a high level of safety.

Intuitive and safe operation without long training

MINICHLORGEN T 30 Skid I is designed for low-maintenance and safe operation. Employees only need to top up the salt solution tank. “Using salt as a starting material is much less dangerous than handling concentrated sodium hypochlorite solution, calcium hypochlorite or chlorine gas. Staff therefore require less protective equipment and special training,” says Beutel. The electrolysis system is operated safely and intuitively via an integrated control unit with a touchscreen. Warning messages make it possible to quickly recognise and rectify problems during operation – without unnecessary and costly shutdowns. According to Beutel, special vacuum dosing technology has also made it possible to reduce the number of pressurised parts in the device, thereby improving reliability and extending maintenance intervals. The sodium hypochlorite solution is also very low in minerals, so there is no need for time-consuming cleaning and descaling of injection points. Room air monitoring using a hydrogen detector rounds off safe operation. “This method enables swimming pool operators to carry out water disinfection with less effort and risk. They can concentrate more on swimming instead of having to worry about complex chemical handling.”

Suitable for private pools and smaller swimming pools

MINICHLORGEN T 30 Skid I is available in several expansion stages with chlorine capacities of 30, 60 and 90 g/h and is therefore equally suitable for private pools and small swimming pools. According to Beutel, operators benefit in particular from needs-based production on site: “Unlike commercially available sodium hypochlorite, which loses up to 1 % of the active chlorine it contains per day during storage, the chlorine content in the sodium hypochlorite of the MINICHLORGEN T 30 Skid I remains stable – as the solution is constantly produced fresh on site.” Thanks to its compact design, it can also be installed in areas where there is usually very little space available. If required, the electrolysis plant can also be connected to standard automation and control systems via RS485 and Modbus interfaces.