The DB Series and UC Series pumps have been a cornerstone of flow battery technology for over two decades, offering unparalleled performance and reliability. These pumps are engineered to meet the unique challenges of flow battery applications, featuring outstanding chemical resistance and non-conductive materials that ensure optimal performance in diverse battery chemistries.

One of the key advantages of Finish Thompson’s pumps is their mag-drive technology, which eliminates the need for mechanical seals. This innovative design not only enhances reliability but also significantly reduces maintenance requirements and potential points of failure. The sealless construction ensures leak-free operation, thereby eliminating the primary cause of failure and improving safety.

The DB Series, known for its compact design and high efficiency, offers a range of benefits tailored to flow battery applications. Its neodymium magnets allow for a space-saving design, while the replaceable shaft and bushing reduce repair costs. The pumps are balanced to ISO 1940 G2.5 standards, ensuring smooth operation with minimal vibration, which is essential for the longevity of flow battery systems.

Complementing the DB Series, the UC Series provides additional options to meet varying flow battery requirements. Both series offer a wide range of pump models, allowing manufacturers to select the perfect fit for different battery sizes and configurations. This versatility, combined with Finish Thompson’s proven reliability, makes these pumps an ideal choice for OEMs, engineers, and facility managers involved in flow battery production and implementation.

The pumps ability to handle a wide range of fluids, coupled with their corrosion-resistant construction, ensures they can withstand the demanding chemical environments typical in flow batteries. This durability translates to reduced downtime and lower total cost of ownership, making Finish Thompson pumps a smart investment for flow battery manufacturers and operators.

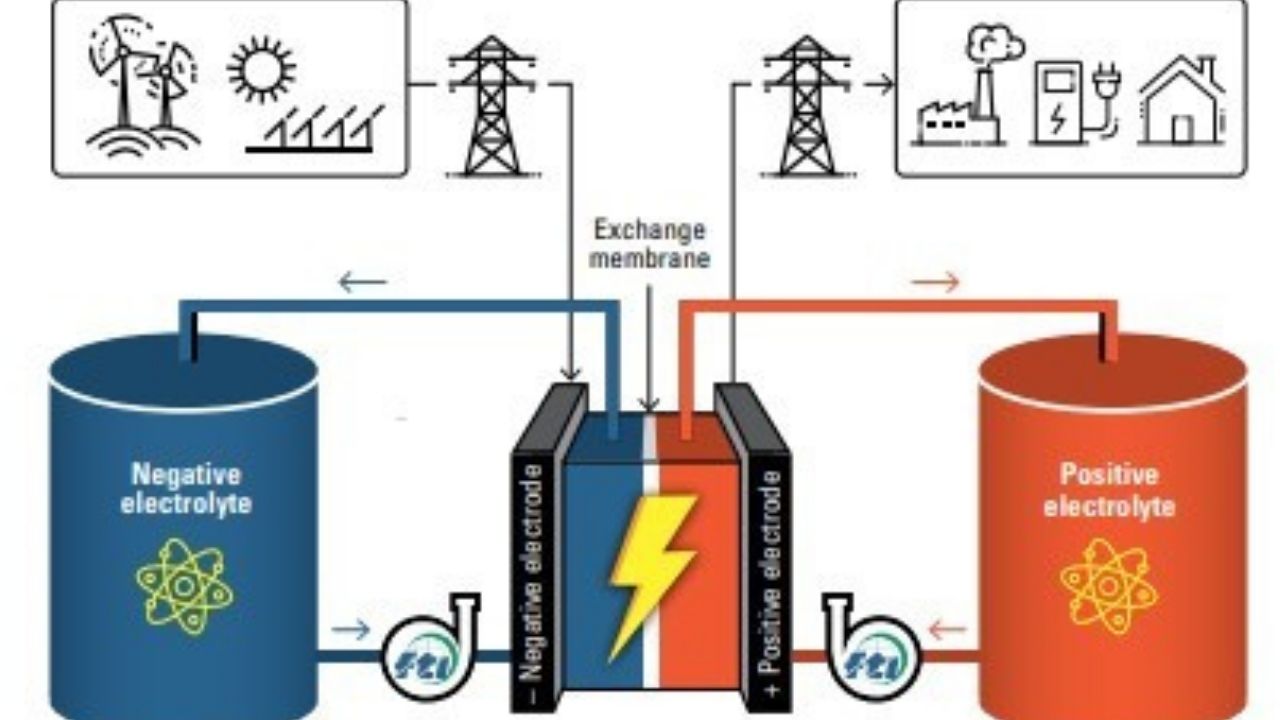

As the renewable energy sector continues to grow, flow batteries are becoming increasingly important for grid-scale energy storage. Finish Thompson’s commitment to innovation and quality positions the company as a key player in this expanding market.

Source: Finish Thompson Inc.