KS screw channel impeller for raw sewage

Just to refresh your memory, three years ago BBA Pumps introduced the new range of mobile sewage pumps. The key to the new design was the special KS screw channel impeller. This allows you to effortlessly pump liquids with large dirt particles and long-fibrous materials. We started off with the BA150KS and BA180KS, 6-inch and 8-inch pumpsets respectively. Last year we added the big 12-inch BA300KS and nowadays many mobile sewage pumps are now in operation worldwide.

The centrifugal pump

A rugged ductile iron pump casing containing a screw channel impeller with a dirt passage of 130 mm. The MP100 double vacuum pump is mounted on top of the heavy duty bearing frame. And the performance of the BA200KS exceeds expectations.

Clean and economical drive

The pump is driven by a clean and economical Perkins diesel engine. The electronically controlled variable speed engine meets the stage V emission requirements. Low fuel consumption and minimal noise emissions are key features of this engine.

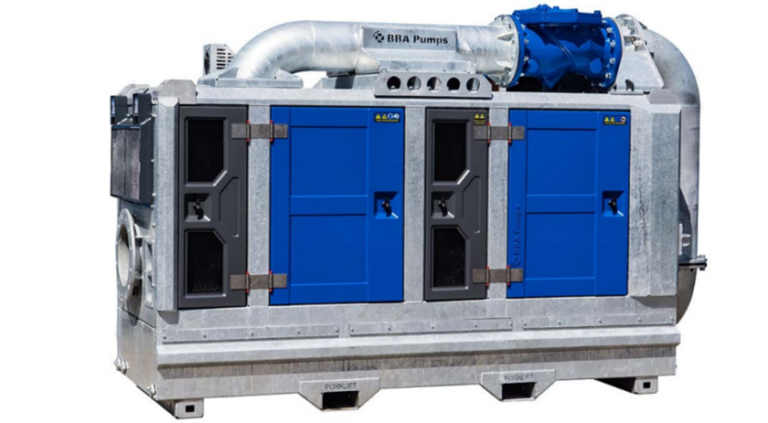

Sound attenuated canopy

BBA Pumps canopies are known as the most innovative and robust in the world. The canopy of the BA200KS has too many features to mention.

- Interior and exterior lighting

- Super quiet, certified sound level LPA 70 dB(A) at 10 m

- Roof discharge pipe ends with a rotatable flange elbow

- 8 lockable doors for easy access to all components

- Multiple lifting eyes

- Stainless steel door hinges grease lubricated

- Hot dip galvanized steel canopy frame

- Large internal fuel and DEF tanks

- External fuel tank connection

- Fully bunded unit eliminating fuel/oil spills

- Fitted with 2 forklift pockets

- Battery isolator switch

- Integrated emergency stop

And much more user friendly and sustainable details!

Energy saving auto level control

With an automatic level control, the BA200KS automatically switches on or off using floats based on the rise and fall of liquid levels in the sewer. With electronically controlled diesel engines we can take this one step further. Here the level is automatically controlled via the use of an optional pressure sensor which regulates the speed of the pumpset.

Source: BBA Pumps BV