Traditionally, achieving a removal efficiency of 105 microns (140 mesh), classified as “fine” grit, has been regarded as a significant accomplishment. However, the introduction of an innovative new system now enables the reliable and cost-effective capture of “ultra-fine” grit, which includes particles as small as 75 microns.

This advanced system integrates three well-established and validated technologies to consistently achieve a 95% removal efficiency for ultra-fine grit down to 75 microns across all flow rates. It ensures consistent performance without derating, across low, average, or peak flow conditions, with a single-unit capacity of up to 50 million gallons per day.

What’s Driving the Adoption of High-Efficiency Grit Removal Systems?

The rising demand for high-efficiency grit removal systems is driven by the need to protect plant infrastructure. This trend is particularly noticeable with the increasing adoption of technologies such as membrane bioreactors (MBRs), specialized pumping equipment, and fine bubble diffusers. Effectively removing ultra-fine grit can yield a substantial return on investment by preventing line blockages, deposition in downstream channels, process basins and reducing the fouling of diffusers and membranes. This, in turn, extends the lifespan of downstream equipment, significantly lowers maintenance costs, and enhances overall operational efficiency.

Ultra-fine grit can also present significant challenges to aeration systems. The accumulated grit disrupts oxygen circulation, decreases the efficiency of biological treatment, and increases compliance costs associated with effluent regulations. This buildup limits the volume necessary for optimal retention times in biological treatment and sludge digestion. Manually removing grit from the bottom of basins can cost between $150,000 and $1,500,000 per cleaning, and the cleaning process risks damaging the aeration infrastructure.

The necessity to tackle ultra-fine grit differs by region and season. Geographic location and environmental factors significantly affect the grit size distribution encountered by wastewater treatment facilities. Coastal regions and agricultural areas face elevated levels of ultra-fine particulate matter, and seasonal factors such as winter road treatments also influence particle size distribution.

As the diameter of grit decreases, the challenge of removal increases. Currently, there are two approaches to ultra-fine grit removal available in the market, each employing a distinct method.

Stacked Tray Systems

Around 15 years ago, the stacked tray system was developed, raising expectations for the removal of ultra-fine grit through gravity-based separation. This method utilizes a series of vertically-mounted trays to expand the surface area in a square settling tank, allowing grit particles to settle gradually from wastewater.

The design features a notable head loss throughout the system, primarily due to the inlet distributor, which evenly disperses the incoming flow across the multiple trays (up to 12 inches / 300 mm). Typically, a continuously operating remote pump is used to remove the grit that accumulates at the bottom of the tank.

While high removal efficiencies are touted for particles as small as 75 microns, efficiencies are typically derated down to 85 percent during peak flow conditions in many of the installations. At such peak flow rates, manufacturers of stacked-tray systems will often only guarantee performance specifications for the removal of particles as small as 212 microns.

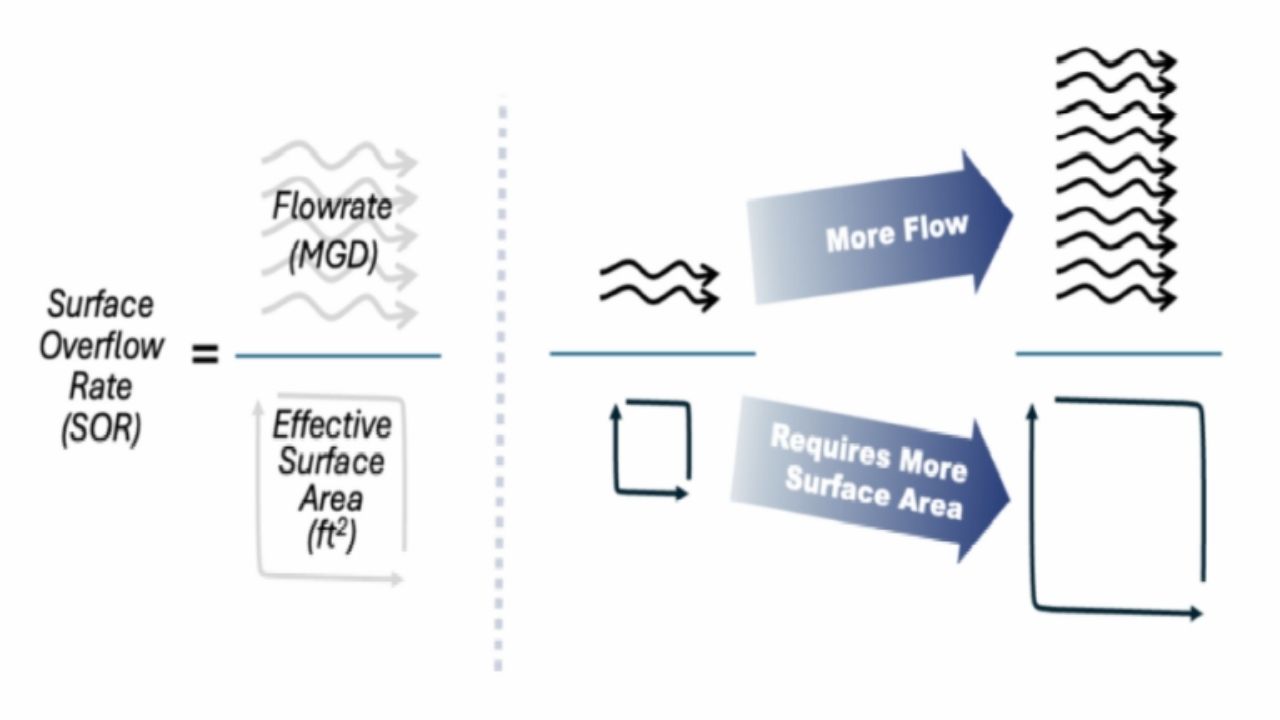

Stacked-tray systems are sized and designed based on surface area and particle settling rates, which determine the number of trays and tank depth required. Increased flow demands more surface area to sustain a Surface Overflow Rate (SOR) that effectively removes fine and ultra-fine grit.

Practical limitations on available surface area restrict system capacity. The largest stacked tray systems can accommodate a maximum of approximately 13 million gallons per day (MGD) for 75-micron removal. To manage larger flows, multiple systems are necessary: 20 MGD requires 2 systems, while 50 MGD demands 4 systems. This not only increases the footprint significantly but also necessitates the duplication of ancillary equipment, such as pumps and grit washing and dewatering systems. The additional equipment increases the owners’ O&M expenses.

Integrating Forced Vortex Technology with Inclined Plates

As the market began to recognize the importance of ultra-fine grit removal while grappling with the capacity limitations of stacked tray systems, engineers at Smith & Loveless took on the challenge of developing a scalable system that could provide consistent and efficient removal of ultra-fine grit across all flow rates, without any performance degradation at low, average, or peak flows.

They developed the PISTA INVORSOR, a solution that merges multiple mature, proven technologies with designer benefits, representing a new generation of the long-established PISTA Grit Removal system. This advanced system effectively achieves 95% grit removal at 75 microns across all flow conditions, from low to peak flows, accommodating flow up to 50 MGD per chamber.

Hydraulic Forced Vortex. This system builds on the features of the PISTA Grit Removal System, which has demonstrated exceptional efficiency in capturing 95% of particles down to 105 microns, across thousands of installations. Forced hydraulic systems aren’t settling devices like most other grit systems; instead, the chamber geometry with patented baffles regulates and optimizes flow velocities to generate a true forced hydraulic vortex path that effectively removes grit. To accomplish this hydraulic action, the systems combine a specifically inclined inlet flume, a circular chamber with a unique flat-floor upper chamber, and a lower collection hopper for intermittent pumping.

Integrated inclined parallel plates. The INVORSOR features an additional stage to remove ultra-fine particles by augmenting the hydraulic forced vortex with an integrated inclined parallel plates. Flow transitions from the hydraulic vortex to an upper hopper, optimized through computational fluid dynamics to effectively remove particles as small as 75 microns. Inclined plates in the upper chamber disrupt the vortex, facilitating a sedimentation process under quiescent conditions.

By augmenting the hydraulic forced vortex with the upper chamber of the inclined parallel plates, the INVORSOR design can achieve a single system capacity up to 50 MGD while maintaining a grit removal efficiency of 95% at 75 microns. (Nine individual models range in capacity from 0.5 MGD up to 50 MGD through a single unit.) In contrast, achieving the same performance with a stacked tray system would necessitate four separate systems, each equipped with its own pumps, gates, as well as grit washing and dewatering systems. This is not just additional capitals cost but also increased maintenance costs.

A key design benefit of the INVORSOR concerns the variable inlet and outlet arrangements available in the design phase, which distinguishes it further from other kinds of vortex grit chambers. The full variability of the inlet and outlet channels enables designers to configure the system to accommodate existing sites and optimize space utilization on new sites.

Flow and Level Control

Scaling up to accommodate higher flow capacity is one key reason why the INVORSOR can effectively replace multiple stacked tray systems. Another crucial factor is its level control, which enables the automatic maintenance of optimal velocity to consistent high-efficiency grit removal across a range of conditions, from minimal flow to peak flow.

Maintaining the optimal velocity is essential for effective grit removal, with an acceptable range of 1.6 to 3.5 ft/sec. If the flow rate falls below this threshold, grit will settle excessively, leading to accumulation in the approaching channel (i.e. grit trapped prior to the grit chamber).

No additional downstream control devices are required to keep the velocity in the preferred range during both peak flow and minimum flow, as the system possesses up to 10:1 turndown.

As illustrated in Chart 1, an alternative solution using four stacked-tray systems, incorporating a submerged weir, sized for a total of 50 MGD struggles to stay within the acceptable velocity range. To address this issue, a complex staging arrangement is required, where a single unit would operate under low flow conditions and additional units would be activated during peak flow events. The INVORSOR, radically simplifies the process, maintaining proper velocity by automatically adjusting to fluctuations in flow, accommodating variations from 5 MGD up to 50 MGD and back down to 5 MGD.

Complete Solution

The INVORSOR is a comprehensive solution designed for effective ultra-fine grit removal. This integrated system combines decades of expertise in market-leading grit removal technology and has been extensively validated in the field.

First, the hydraulic forced vortex with flat floor design effectively removes large, medium, and fine grit while requiring minimal maintenance and energy.

Second, it features an integrated inclined plates optimized through computational fluid dynamics analysis and extensive validation in the field for effective ultra-fine grit removal in systems up to 50 MGD.

Lastly, the INVORSOR works seamlessly with Smith & Loveless grit washing and dewatering systems to ensure true ultra-fine grit removal efficiency throughout the entire process. Grit washing and dewatering are key in maintaining the true grit removal efficiency achieved by the INVORSOR. High removal efficiency grit chambers are not ultimately effective if the secondary dewatering equipment is unable to maintain similar capture and removal performance. Thus, the complementary grit concentrator / hydrocyclone and grit screw conveyor / classifier technologies by S&L include unique components for processing and removing finer and drier grit. For example, inside the optimally-sized conveyor/classifier an energy dissipation zone slows down the grit slurry coming off the concentrator/hydrocyclone and into an inclined parallel plate zone that entraps the finer particles for disposal versus having to recycle the finer particles back to the headworks. A double-sided weir in the screw hopper allows for enhanced grit settling velocities by reducing the surface overflow rate.

The significant reduction in water and putrescible organic content can significantly reduce disposal cost, odor control concerns, and allow the downstream treatment plant equipment to operate more efficiently, which is the overall purpose of an advance grit removal system like INVORSOR.

By: Rich MacGregor, Technical Writer

Source: Smith & Loveless Inc.